在绕组的设计环节,会通过路数的合理调整和分配,确保电磁线与引接线的均匀性连接,更多情况下,可以从绕组引接线的数量,推断出绕组连接的路数,即一路的头尾各连接一根引接线,而后通过引接线的关联关系,进而实现绕组的并绕连接关系。

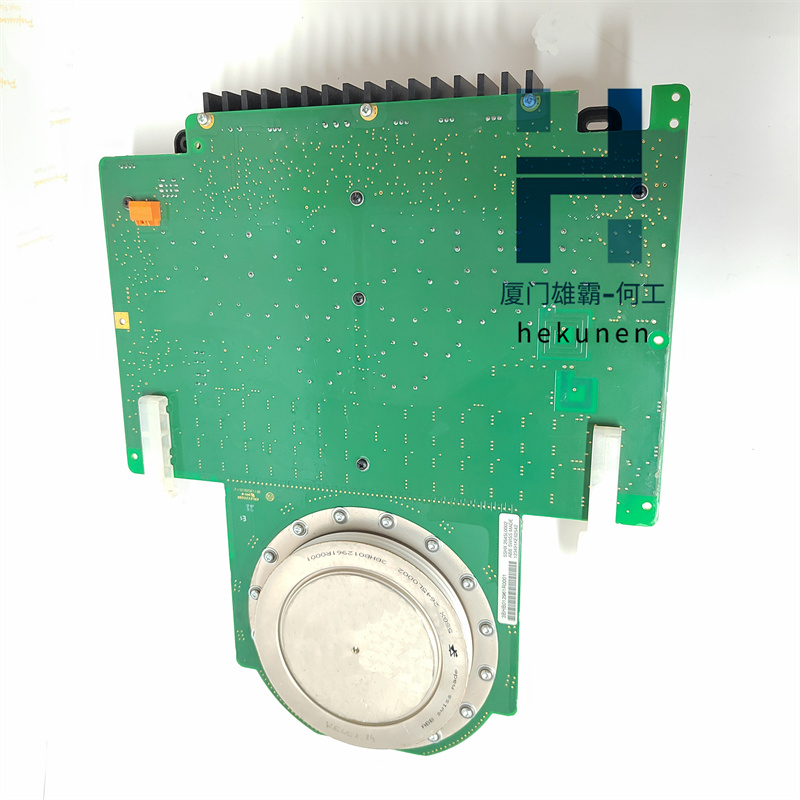

除引接线与绕组本体的连接外,在一些大型电机上,也会通过母线的方式连接,即将需要并联的绕组本线连接到母线上,需要并联的引接线也连接到母线上,这样就大大简化了本线与引接线连接的问题,引接线直径的选择也就有了更大的自由度。对于连接母线,可以按照电机产品的实际空间,选择不同的线型,铜排就是比较常见的一种。

对于引接线与绕组本线的连接,连接可靠性是一个非常关键的控制环节,不同的绕组型式,需要不同的连接工艺保证。

In the design process of the winding, the reasonable adjustment and allocation of the number of paths will ensure the uniform connection between the electromagnetic wire and the lead wire. In most cases, the number of paths connected to the winding can be inferred from the number of lead wires in the winding, that is, one lead wire is connected to each end of the winding, and then the parallel winding connection relationship of the winding can be achieved through the correlation relationship between the lead wires.

In addition to the connection between the lead wire and the winding body, in some large motors, it is also connected through the busbar, that is, the winding that needs to be parallel is connected to the busbar, and the lead wire that needs to be parallel is also connected to the busbar. This greatly simplifies the problem of connecting the main wire to the lead wire, and the selection of the lead wire diameter also has greater freedom. For connecting busbars, different line types can be selected according to the actual space of the motor product, and copper bars are a common type.

For the connection between the lead wire and the winding main line, the reliability of the connection is a crucial control link, and different winding types require different connection processes to ensure.