服务热线

13313705507

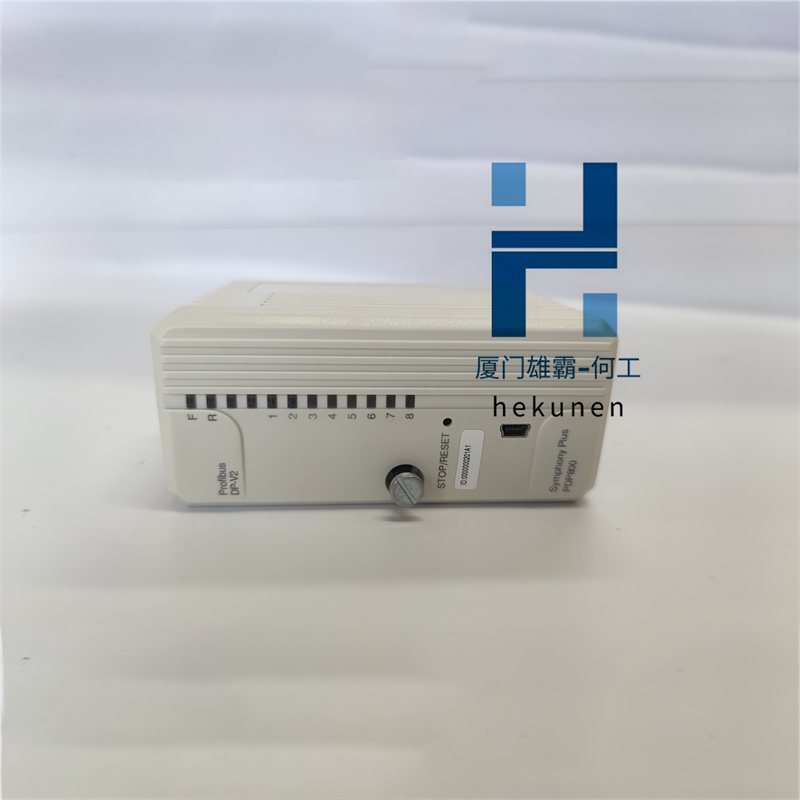

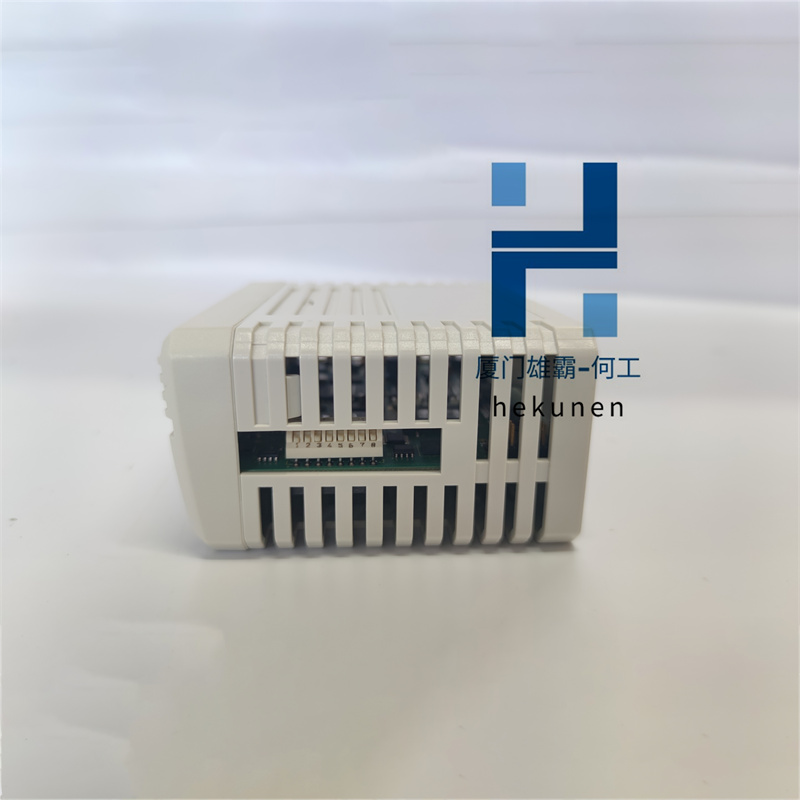

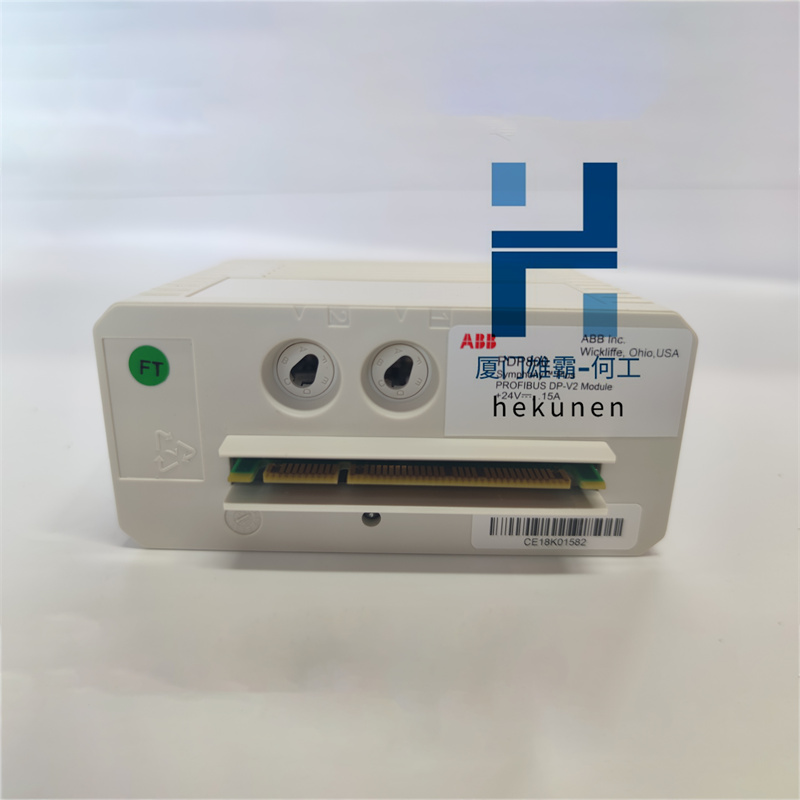

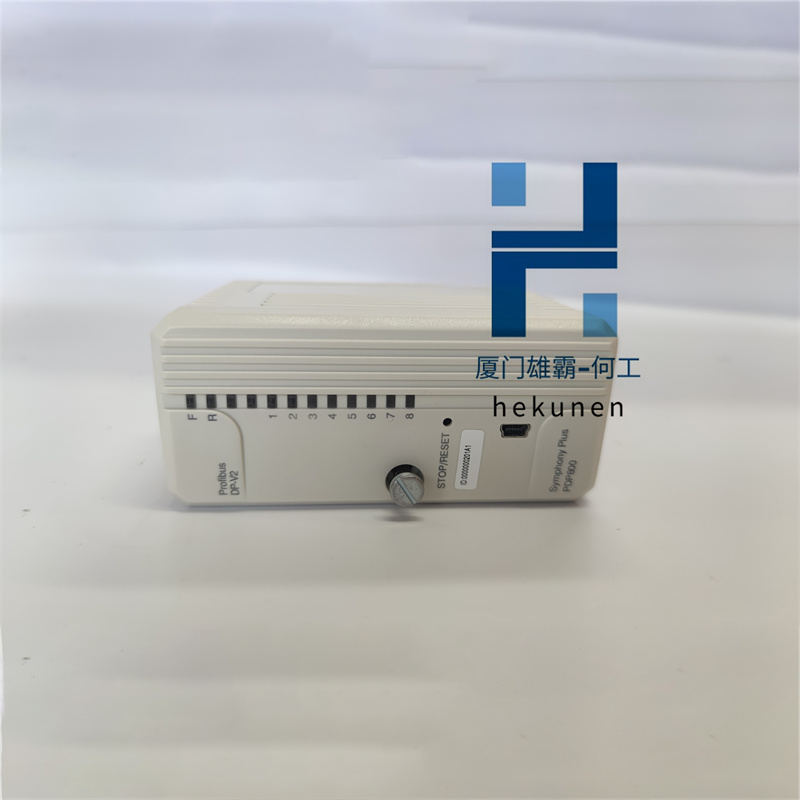

型号: ABB PDP800

分类: ABB系统备件

联系人:何经理

手机:13313705507

QQ:2235954483

邮箱:2235954483@qq.com

地址:厦门市思明区吕岭路1733号万科创想中心2009室

行业应用

IC高速分选机——转塔式分选机

行业背景

随着新兴的智能设备市场需求激增, IC芯片的应用和发展得到大幅提升,常见如汽车电子和消费电子、5G、物联网以及工业机器人产业等领域,均有广泛应用。

同时随着半导体技术不断发展,芯片线宽尺寸不断减小,制造工序也逐渐复杂。目前国际7nm 制程需要将近2000道工序,先进的制程和复杂的工序将持续提升对先进设备的需求。

工作原理

分选机主要应用于芯片设计检验阶段和成品终测(FT)环节,是终测环节重要检测设备之一。

转塔式分选机尤其适用于小型片式半导体分立元件的打标、测试、分选和包装,是一种主转盘在中心,各个测试工位按照顺序均布在主电机周围的一种高速分选机,通常包含工位有16个和24个等多种型号。

产品通过上料结构被送到主电机转盘上;

主电机转盘吸住芯片并通过转动将产品送到下一个工位;

上料工位工作;

主电机转盘吸取新的一个产品。

特点

主电机每转动一格,都会将产品送到各个工位,有产品的工位将对产品进行测试等处理,如此周而复始

同一时间会有多个工位对多个产品进行处理

占地面积小、精度高、速度快

技术难点

转塔式分选机的优点是设备的每小时产量较高,当前市场上速度快的设备每小时可以完成5-6万及更多枚芯片的测试。

目前转塔式分选机国产自给率低,因其 UPH(每小时分选芯片数量)是高的一类分选机,在高速运行下,既要保证重复定位精度,又要保证较低的 Jam Rate(故障停机比率), 这对分选机设备开发提出了更高的要求。

尤其随着半导体行业的快速发展,主转盘工位(高速转塔)的运行速度、转动精度、振动幅度和跳动幅度等因素决定了高速分选机的生产效率和稳定性,是整台设备的高效运行的核心,这也对高速转塔工位应用的转盘直驱马达的精度、速度、稳定性要求越来越高。

常规转塔式测试分选机技术要求

16-24个工位/旋转角度:15°~22.5°

单工位转动时间:18~22ms

转盘惯性:0.003~0.020 kg.m2

测试时间:35~60ms

产能:40~60 k UPH

向下/向上Z轴的平均移动时间:3~20ms

雅科贝思应用方案

主转盘直驱方案

主转盘转动是高速分选机重要的运动之一,而主转盘驱动状况取决于选取的主电机性能,雅科贝思ADR-H系列能足够满足转塔应用的此类运动曲线,非常适用于高精度的移动、速度响应要求高和对端跳要求较高的场合。

从运动控制的角度看,该过程在技术上极具挑战性:它需要转塔电机以非常高的速度运行并承受振动。搭载雅科贝思为高速分选机的直驱马达定制的伺服驱动器,使速度稳定性进一步提高。

Industry applications

IC high-speed sorting machine - rotary tower sorting machine

Industry background

With the surge in demand in the emerging smart device market, the application and development of IC chips have been greatly improved, commonly used in fields such as automotive electronics and consumer electronics, 5G, the Internet of Things, and industrial robotics industry.

At the same time, with the continuous development of semiconductor technology, the chip linewidth size is constantly decreasing, and the manufacturing process is gradually becoming more complex. At present, the international 7nm process requires nearly 2000 processes, and advanced processes and complex processes will continue to increase the demand for advanced equipment.

operational principle

Sorting machines are mainly used in the chip design inspection stage and the final product testing (FT) stage, and are one of the important testing equipment in the final testing stage.

The rotary tower sorting machine is particularly suitable for marking, testing, sorting, and packaging of small chip semiconductor discrete components. It is a high-speed sorting machine with a main turntable in the center and various testing stations arranged uniformly around the main motor in order. It usually includes multiple models such as 16 and 24 stations.

The product is delivered to the main motor turntable through the feeding structure;

The main motor turntable sucks the chip and rotates it to deliver the product to the next workstation;

Working at the loading station;

The main motor turntable draws a new product.

characteristic

Every time the main motor rotates one grid, it will send the product to each workstation, and the workstation with the product will conduct testing and other processing on the product. This cycle repeats itself

Multiple workstations will process multiple products at the same time

Small footprint, high accuracy, and fast speed

Technical difficulties

The advantage of a rotary tower sorting machine is that the equipment has a high hourly output, and the fastest equipment on the current market can complete testing of 50-60000 or more chips per hour.

At present, the self-sufficiency rate of domestically produced turret sorting machines is the lowest, as their UPH (number of sorting chips per hour) is the highest type of sorting machine. Under high-speed operation, it is necessary to ensure both repeated positioning accuracy and lower Jam Rate (failure shutdown rate), which puts higher requirements on the development of sorting machine equipment.

Especially with the rapid development of the semiconductor industry, factors such as the operating speed, rotational accuracy, vibration amplitude, and jumping amplitude of the main turntable station (high-speed turntable) determine the production efficiency and stability of the high-speed sorting machine, which is the core of the efficient operation of the entire equipment. This also requires increasingly high precision, speed, and stability of the turntable direct drive motor used in high-speed turntable stations.

·

Technical requirements for conventional turret test sorting machines

·

·

16-24 workstations/rotation angle: 15 °~22.5 °

·

·

Single station rotation time: 18-22ms

·

·

Rotary table inertia: 0.003~0.020 kg.m2

·

·

Test time: 35-60ms

·

·

Capacity: 40-60 k UPH

·

·

Average movement time of Z-axis down/up: 3-20ms

·

IELTS application solution

Main turntable direct drive scheme

The rotation of the main turntable is one of the most important movements of a high-speed sorting machine, and the driving condition of the main turntable depends on the performance of the selected main motor. The Yacobesi ADR-H series can meet the motion curve of the rotary tower application sufficiently, and is very suitable for high-precision movement, high speed response requirements, and high end jump requirements.

From the perspective of motion control, this process is technically challenging: it requires the turret motor to operate at very high speeds and withstand vibrations. Equipped with a servo driver customized by Yacobesi for the direct drive motor of the high-speed sorting machine, the speed stability is further improved.

如果您有任何问题,请跟我们联系!

联系我们