服务热线

13313705507

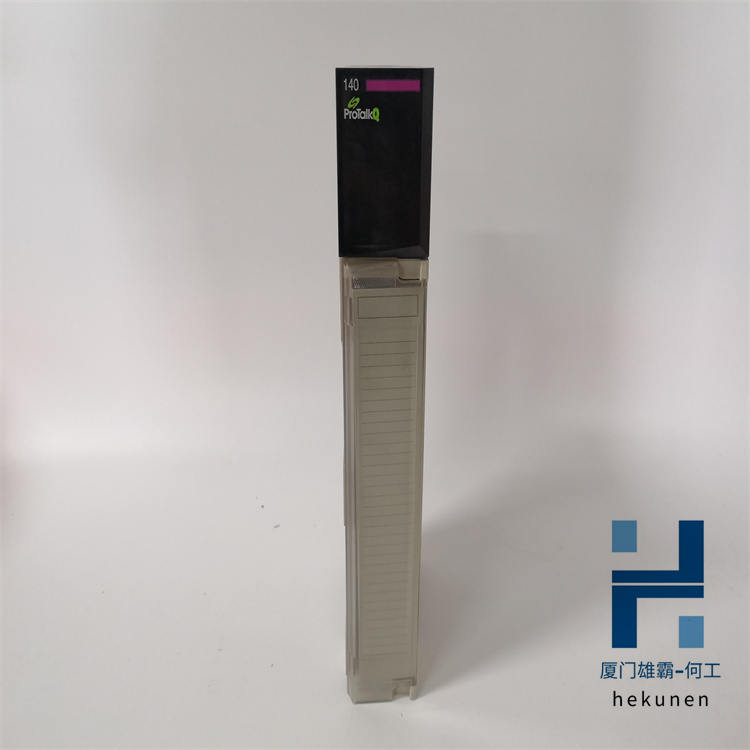

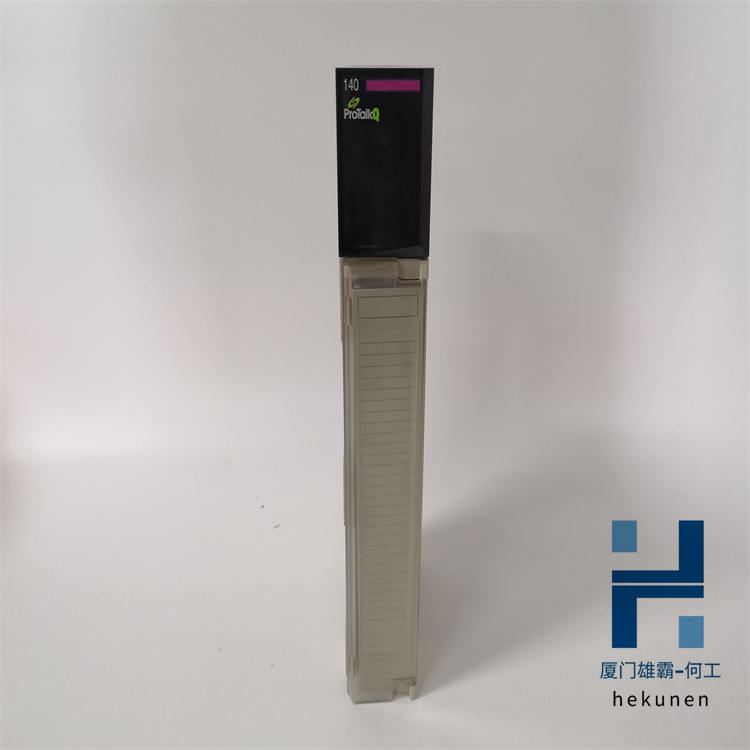

型号: 5301-MBP-DFCM

分类: PROSOFT

联系人:何经理

手机:13313705507

QQ:2235954483

邮箱:2235954483@qq.com

地址:厦门市思明区吕岭路1733号万科创想中心2009室

在高性能、多轴、同步运动应用中,控制时序要求是的、确定的和时间关键的,并且要求大限度地减少端到端延迟,尤其是在控制周期时间变短和控制算法复杂性增加的情况下。这些高性能应用程序需要具有亚毫秒网络周期时间的实时连接,以控制复杂的运动应用程序。

智能制造使用视觉系统和运动应用程序来监控制造质量并提高生产安全性。工业以太网必须支持实时确定性运动控制流量和尽力而为的视觉流量在同一网络上的共存,高可达 Gb 带宽。

连接到网络的设备和控制器的互操作性需要在整个制造设施中提供无缝数据流,并确保数据对更别的管理系统透明,同时通过减少调试时间使这些网络更加灵活和可扩展。融合 (IT/OT) 以太网网络可确保将运动洞察无缝访问到更别的管理软件系统,以进行分析、优化制造流程并加速数字化转型。

先进的传感解决方案创建运动洞察力,可用于优化制造流程和检测故障的早期迹象。传感方式包括位置、电流、电压、磁场、温度、振动和冲击。通过使用先进的传感技术来部署对资产健康状况的实时监控,以提供基于增加资产正常运行时间的预测性维护服务合同,正在创建新的商业模式。先进的传感要求包括在恶劣的工业环境(例如,有大量灰尘的环境)中的稳健性、的位置传感、非接触式大电流传感、高带宽电流和振动传感、减少校准以确保解决方案的准确性以及小解决方案尺寸用于编码器类型的应用。

智能制造的下一代智能运动控制解决方案需要多种技术组合。这些技术结合使用时,可为严苛的工业部署提供强大、的运动控制,并通过先进传感获得系统洞察力。

复杂的运动控制需要精密转换器技术来实现高质量的电流反馈,利用隔离和非隔离解决方案来提供高度和快速瞬态响应的控制回路性能。电流反馈是增强驱动性能的基本组成部分,并决定了整体控制带宽和响应时间。电流反馈的关键要求包括与 PWM 周期同步测量、隔离或高共模测量、低偏移漂移以大限度地减少扭矩纹波,以及以 14 至 18 位分辨率进行低延迟同步采样以测量相电流。编码器和直线轨道应用中的位置测量也需要精密转换器技术,以提供更大的吞吐量并提高生产率。

以下是我司【主营产品】,有需要可以发来帮您对比下价格哦!

主营:世界品牌的PLC 、DCS 系统备件 模块

①Allen-Bradley(美国AB)系列产品》

②Schneider(施耐德电气)系列产品》

③General electric(通用电气)系列产品》

④Westinghouse(美国西屋)系列产品》

⑤SIEMENS(西门子系列产品)》

⑥销售ABB Robots. FANUC Robots、YASKAWA Robots、KUKA Robots、Mitsubishi Robots、OTC Robots、Panasonic Robots、MOTOMAN Robots。

⑦estinghouse(西屋): OVATION系统、WDPF系统、MAX0系统备件。

⑧Invensys Foxboro(福克斯波罗):I/A Series系统,FBM(现场输入/输出模块)顺序控制、梯形逻辑控制、事故追忆处理、数模转换、输入/输出信号处理、数据通信及处理等。Invensys Triconex: 冗余容错控制系统、基于三重模件冗余(TMR)结构的现代化的容错控制器。

⑨Siemens(西门子):Siemens MOORE, Siemens Simatic C1,Siemens数控系统等。

⑩Bosch Rexroth(博世力士乐):Indramat,I/O模块,PLC控制器,驱动模块等。

◆Motorola(摩托):MVME 162、MVME 167、MVME1772、MVME177等系列。

PLC模块,可编程控制器,CPU模块,IO模块,DO模块,AI模块,DI模块,网通信模块,

以太网模块,运动控制模块,模拟量输入模块,模拟量输出模块,数字输入模块,数字输出

模块,冗余模块,电源模块,继电器输出模块,继电器输入模块,处理器模块。

In high performance, multi-axis, synchronized motion applications, control timing requirements are precise, deterministic, and time critical, with a requirement to minimize end-to-end latency, especially as control cycle times get shorter and control algorithm complexity increases. These high performance applications require real-time connectivity with sub-ms network cycle time to control complex motion applications.

Smart manufacturing uses vision systems alongside motion applications to monitor manufacturing quality and increase production safety. Industrial Ethernet networks must support the coexistence of both real-time deterministic motion control traffic and best-effort vision traffic on the same network up to Gb bandwidth.

The interoperability of devices and controllers connected to the networks is required to deliver seamless data flow throughout the manufacturing installation and ensures data transparency to the higher-level management systems while making these networks more flexible and scalable by reducing commissioning time. A converged (IT/OT) Ethernet network ensures seamless access of motion insights to the higher-level management software systems, for analysis, to optimize the manufacturing flow and accelerate digital transformation.

Advanced sensing solutions create motion insights that can be used to optimize the manufacturing flow and detect early signs of failure. Sensing modalities include position, current, voltage, magnetic field, temperature, vibration, and shock. New business models are being created by using advanced sensing to deploy real-time monitoring of an asset’s health to provide predictive maintenance services contracts based on increasing asset uptime. Advanced sensing requirements include robustness in harsh industrial environments (for example, those with a lot of dust), accurate position sensing, contactless high current sensing, high bandwidth current and vibration sensing, reduced calibration to ensure accuracy of the solutions, and small solution sizes for encoder type applications.

A combination of technologies is required for the next generation of intelligent motion control solutions for smart manufacturing. These technologies when combined deliver robust, precise motion control for harsh industrial deployments with access to system insights from advanced sensing.

Complex motion control requires precision converter technologies for high quality current feedback utilizing both isolated and non-isolated solutions to provide control loop performance that is both highly accurate and has fast transient response. Current feedback is the fundamental building block to enhancing drive performance and determines the overall control bandwidth and response time. Key requirements for current feedback include synchronized measurement with PWM cycle, isolated or high common-mode measurement, low offset drift to minimize torque ripple, and low latency simultaneous sampling at 14- to 18-bit resolution to measure phase currents. Precision converter technologies are also required for accurate position measurements in encoders and linear track applications that can deliver greater throughput and increase productivity.

如果您有任何问题,请跟我们联系!

联系我们