服务热线

13313705507

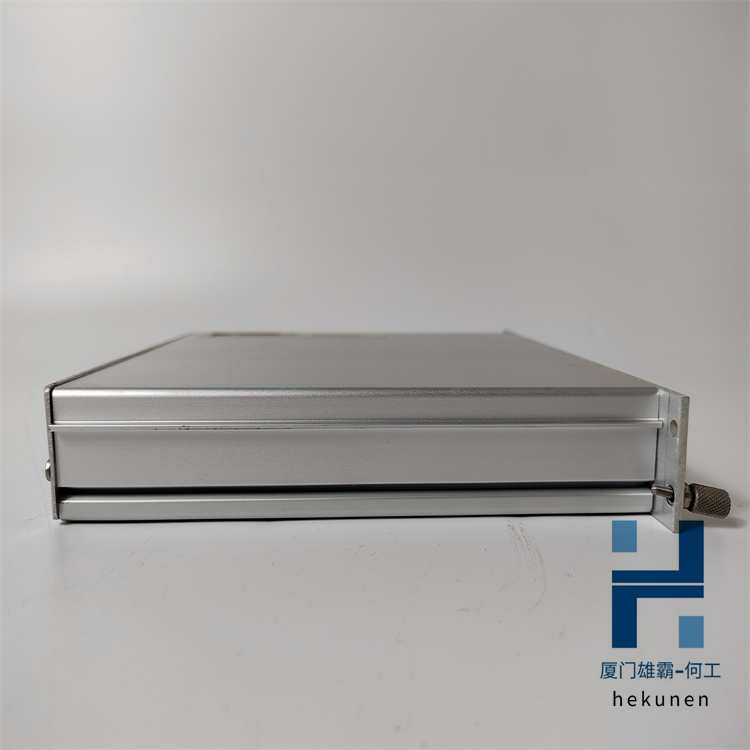

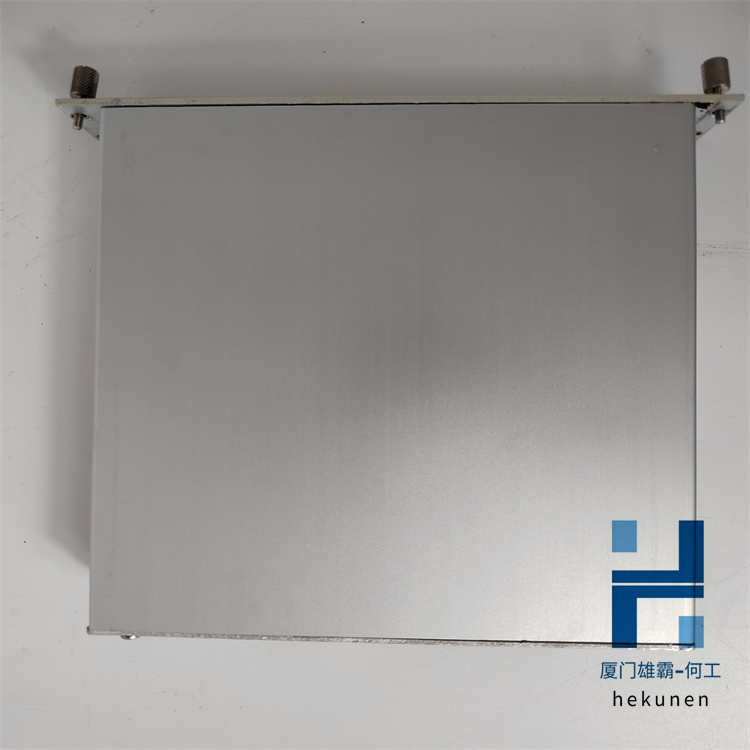

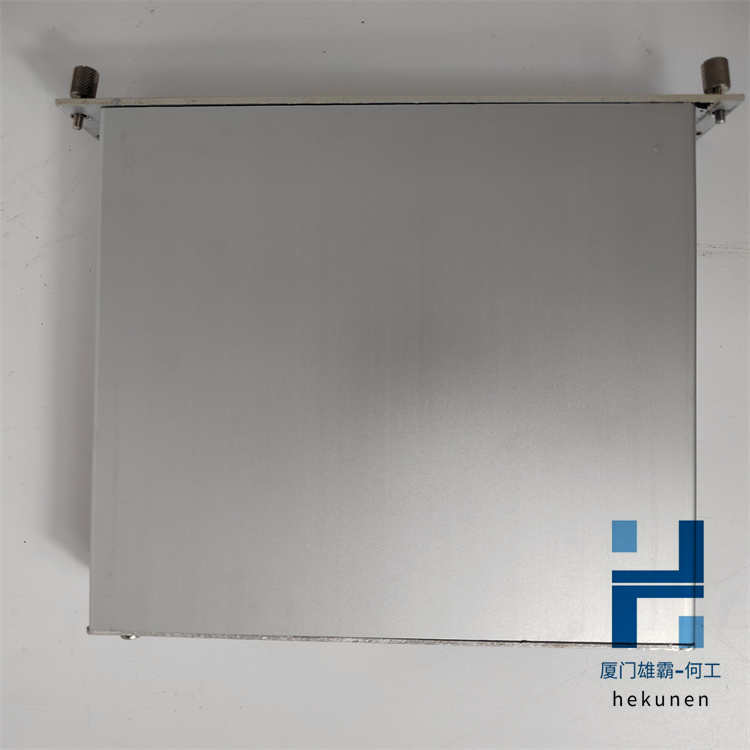

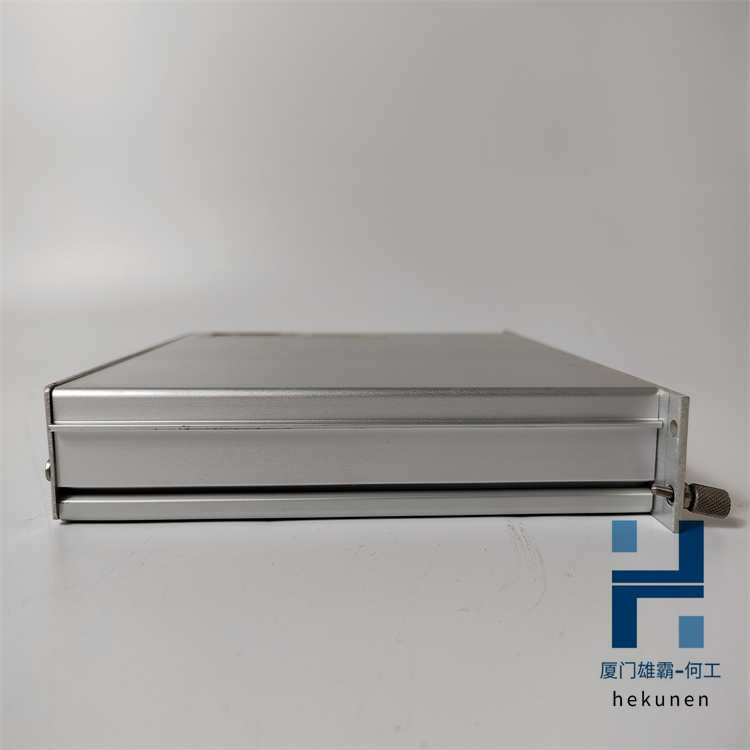

型号: PXIE-6556

分类: NI

联系人:何经理

手机:13313705507

QQ:2235954483

邮箱:2235954483@qq.com

地址:厦门市思明区吕岭路1733号万科创想中心2009室

完全分散的自动化平台将设备带入现场,无需控制柜。Vario-X 与数字孪生技术相结合,可在自动化和控制项目的所有阶段节省时间和金钱:从规划到安装、操作和服务。

不断增长的数字化和更短的开发周期,不断增加的客户需求和熟练工人的短缺,自动化世界正在以惊人的速度发生变化。

新技术正在实施一个模块化的、高度灵活的自动化平台,该平台允许完全分散地实施所有自动化功能(即无需控制柜)。

Vario-X 将传感器和执行器直接带入控制环境,确保可靠的电压、信号、数据管理和分散式伺服驱动器的无缝集成。

Vario-X 的核心是坚固的 IP67 级防水和防尘模块,其中包括电源、控制装置、断路开关、安全技术和 I/O 连接。它们可以很容易地并排组装在带有集成机械安装型材的坚固背板上。

组装后,Vario-X 解决方案可以轻松连接到所有常见的安装系统,无需进一步保护,在情况下,它足够坚固,可以踩踏而不会损坏。Vario-X 配备多核 CPU,可满足所有控制要求,并作为开放式控制平台轻松集成到所有更别的工业以太网中。

设备的安装和布线采用标准 M12 和 MQ15 连接器即插即用,消除了接线错误并缩短了组装时间。这也消除了控制柜中昂贵且耗时的安装工作,例如填充组件、剥线和接地线、标记和接地单个组件。

为了扩展机器控制的模块化概念,可以轻松地在机器周围分布额外的工作站并相互连接,例如添加额外的电源以支持本地化伺服电机。

同样,远程 IO 模块可以直接连接到 Vario-X 以处理和控制传感器和执行器,而无需背板或机柜 I/O。这限制了控制硬件的变体,并大大简化了电缆架构。

Vario-X 正在推动制造过程的电气化,并提供比气动更有效的替代方案。效率仅为 10% 到 20%,由于系统中的无数泄漏和低效的执行器,使用压缩空气作为能源浪费了太多的能源。

用电动代替气动,用伺服电机代替气缸,为所有相关人员带来优势。这包括可以减少机器中低效、低分辨率和相对昂贵的气动装置的工程师,可以专注于一种物理能源——电力的生产计划人员,终可以在明显更安静的工作环境中工作并通过减少能源来操作的员工用来帮助我们的星球。

我司产品广泛应用于数控机械 冶金,石油天然气,石油化工,

化工,造纸印刷,纺织印染,机械,电子制造,汽车制造,

塑胶机械,电力,水利,水处理/环保,市政工程,锅炉供暖,能源,输配电。

Growing digitalization and shorter development cycles, increasing customer requirements and a shortage of skilled workers, the world of automation is changing at breakneck speed.

New technology is implementing a modular, highly flexible automation platform that allows all automation functions to be implemented completely decentrally (i.e. without a control cabinet).

Vario-X brings sensors and actuators directly into the control environment and ensures reliable voltage, signal, data management and the seamless integration of decentralized servo drives.

At the heart of Vario-X are robust, IP67 rated waterproof and dustproof modules, which include power supplies, controls, disconnect switches, safety technology and I/O connections. They can be easily assembled side by side on a rugged backplane with integrated mechanical mounting profiles.

Once assembled, the Vario-X solution can be easily attached to all common mounting systems without further protection and, in extreme cases, is rugged enough to be stepped on without damage. Equipped with a multicore CPU, Vario-X can meet all control requirements and be easily integrated into all higher-level Industrial Ethernet networks as an open control platform.

The installation and cabling of devices is plug-and-play with standard M12 and MQ15 connectors, eliminating wiring errors and reducing assembly time. This also eliminates expensive and time-consuming installation work in the control cabinet like populating components, stripping and landing wires, labeling and grounding individual components.

To extend the modular concept for your machine control, additional stations can easily be distributed around the machine and connected to each other, like adding an additional power supply to support localized servo motors.

Likewise, remote IO modules can be connected directly to Vario-X to process and control sensors and actuators without a backplane or cabinet I/O. This limits control hardware variants and vastly streamlines the cable architecture.

Vario-X is driving forward the electrification of manufacturing processes and offers a much more efficient alternative to pneumatics. With an efficiency of only ten to twenty percent, far too much energy is wasted by using compressed air as an energy source due to countless leaks in the system and inefficient actuators.

Replacing pneumatics with electrics, swapping an air cylinder with a servo motor, brings advantages to all those involved. This includes the engineer who can reduce the inefficient, low resolution and relatively expensive pneumatics in his machine, the production planner who can focus on one physical energy source – electricity, the employees who can finally operate in a noticeably quieter work environment and by reducing energy use to help our planet.

如果您有任何问题,请跟我们联系!

联系我们