服务热线

13313705507

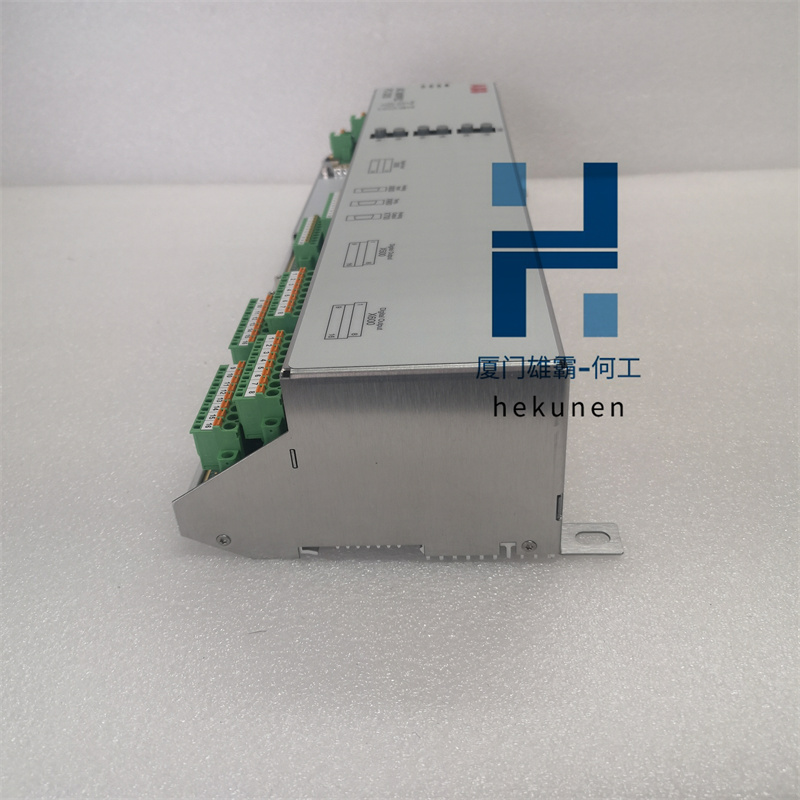

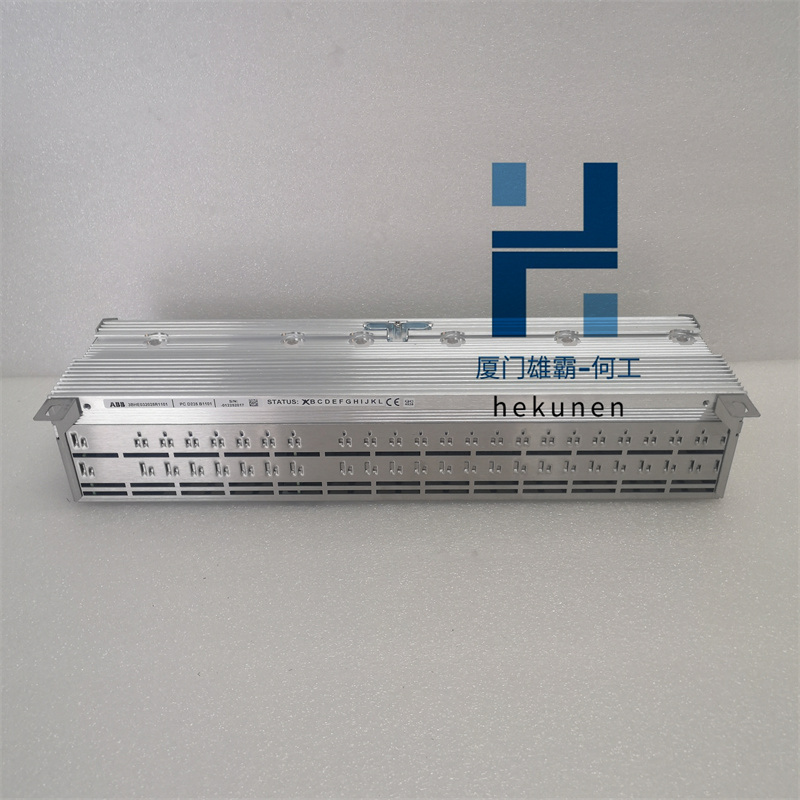

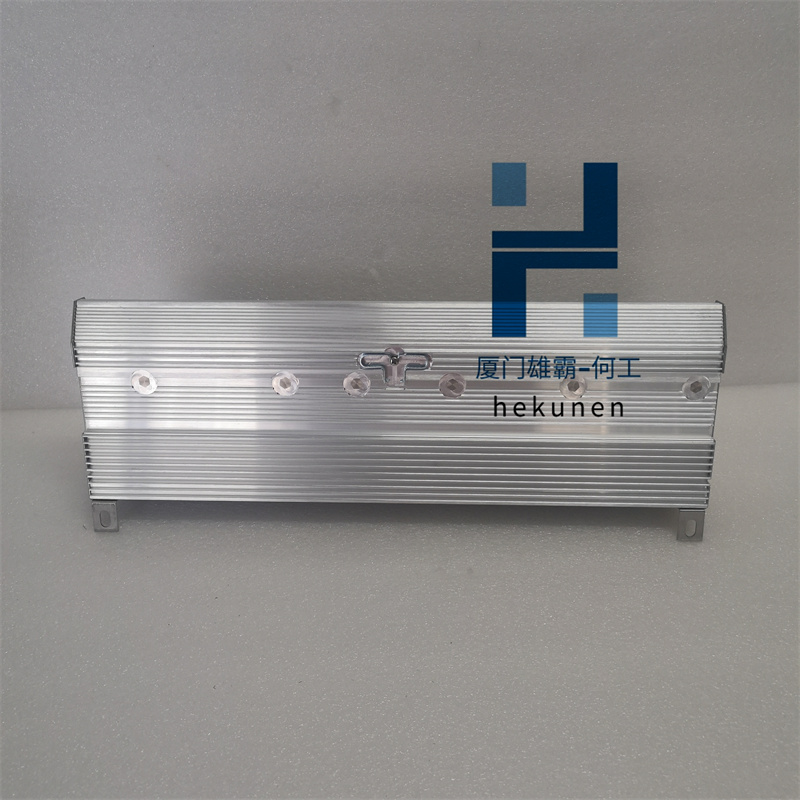

型号: ABB PDD200A101 3BHE019633R0101

分类: ABB系统备件

联系人:何经理

手机:13313705507

QQ:2235954483

邮箱:2235954483@qq.com

地址:厦门市思明区吕岭路1733号万科创想中心2009室

任何一款电器产品,当然包括电机产品,都对其正常运行的额定电压进行了规定,任何的电压偏离均会对电器的正常运行造成不良后果。

对于相对较高端的设备,采用了必要的保护装置,当电源电压出现异常时,采用切断电源的方式进行了保护,对于非常精密的仪器,则采用恒压电源进行调整,而电机产品,特别是工业用电机产品,采用恒压装置的可能性极小,断电保护的情况更多一些。

对于单相电机,只存在电压高与低两种情况,而对于三相电机还存在电压的平衡问题,这三种电压偏离对影响的直接表现为电流增大或电流不平衡。

电机的技术条件中规定,电机的额定电压上下偏差不能超过10%,电机的转矩与电机端电压的平方成正比,当电压过高时,电机铁芯将处于磁饱和状态,定子电流的增大将导致绕组严重发热,甚至出现绕组烧毁的质量问题;而对于电压偏低的情况,一种是电机的启动可能会存在问题,特别是对于带载运行的电机,为了满足电机的带载运行,电流也必须要增加,电流增加的后果同样是绕组的发热乃至烧毁,特别是长期的低压运行,该问题更为严重。

三相电机电压不平衡,是典型的供电电源问题,当电压不平衡时,势必会导致电机电流的不平衡问题。不平衡电压的负序分量在电机气隙中产生一个与转子转向相反的磁场。电压中很小的负序分量可能使得流过绕组的电流比电压平衡时的电流大很多。流过转子导条中的电流频率几乎是额定频率的2倍,因此转子导条中的电流挤流效应使得转子绕组的损耗增加值比定子绕组损耗增加值大很多。定子绕组温升比在平衡电压下运行时的温升增高。

当电压不平衡时,电动机的堵转转矩、小转矩以及大转矩都将减小。若电压不平衡很严重,则电动机将不能正常工作。

当电动机在不平衡电压下满载运行时,由于转差率随着转子附加损耗的增加而增大,因而此时转速会略微下降。随同电压(电流)不平衡程度的增大,电动机的噪声和振动可能增强。振动可能损害电动机或整个驱动系统。

为了有效甄别电机电压不平的原因,可能通过电源电压检测或电流变化情况的方法进行。大多数设备上都配有电压监控仪表,可以通过数据对比进行分析,而对于没有监控装置的情况,则应采用定期检测或测定电流的方式进行;对于可以正反转的电机,在不影响被拖动设备的情况下,可以任意调换两相供电线,观察电流变化情况,而间接分析电压的平衡情况,在排除电压不平的问题后,可能就会涉及匝间、相间等质量问题。

Any electrical product, including motor products, has specified the rated voltage for its normal operation, and any voltage deviation will cause adverse consequences to the normal operation of the electrical appliance.

For relatively high-end equipment, necessary protective devices are used. When the power supply voltage is abnormal, the power supply is cut off for protection. For very precise instruments, constant voltage power supply is used for adjustment. However, for motor products, especially industrial motor products, the possibility of using constant voltage devices is very small, and there are more situations of power outage protection.

For single-phase motors, there are only two types of voltage: high and low, while for three-phase motors, there is also a voltage balance problem. The direct impact of these three voltage deviations is an increase in current or an imbalance in current.

According to the technical specifications of the motor, the deviation between the rated voltage of the motor cannot exceed 10%, and the torque of the motor is proportional to the square of the motor terminal voltage. When the voltage is too high, the motor core will be in a magnetic saturation state, and an increase in stator current will cause serious heating of the winding, even leading to quality problems such as winding burnout; For situations where the voltage is low, one possibility is that there may be problems with the starting of the motor, especially for motors operating under load. In order to meet the load operation of the motor, the current must also increase. The consequence of the current increase is also the heating or even burning of the winding, especially for long-term low-voltage operation, which is even more serious.

The voltage imbalance of three-phase motors is a typical power supply problem. When the voltage is unbalanced, it will inevitably lead to the imbalance of motor current. The negative sequence component of unbalanced voltage generates a magnetic field in the motor air gap that is opposite to the rotation of the rotor. The small negative sequence component in the voltage may cause the current flowing through the winding to be much larger than the current at voltage balance. The frequency of the current flowing through the rotor conductor is almost twice the rated frequency, so the current squeezing effect in the rotor conductor causes the increase in losses of the rotor winding to be much greater than that of the stator winding. The temperature rise of the stator winding is higher than that when operating under balanced voltage.

When the voltage is unbalanced, the locked rotor torque, small torque, and large torque of the motor will all decrease. If the voltage imbalance is severe, the motor will not function properly.

When the motor operates at full load under unbalanced voltage, the speed will slightly decrease due to the increase in slip rate as the additional loss of the rotor increases. As the degree of voltage (current) imbalance increases, the noise and vibration of the motor may increase. Vibration may damage the electric motor or the entire drive system.

To effectively identify the cause of uneven motor voltage, methods such as power supply voltage detection or current changes may be used. Most devices are equipped with voltage monitoring instruments, which can be analyzed through data comparison. However, for situations without monitoring devices, regular testing or current measurement should be used; For motors that can rotate in both directions, without affecting the dragged equipment, the two-phase power supply lines can be freely swapped to observe the current changes, and indirectly analyze the voltage balance. After eliminating the problem of uneven voltage, quality issues such as turn to turn and phase to phase may be involved.

如果您有任何问题,请跟我们联系!

联系我们